250mm x 50mm Metallic trunking Knockout

250mm x 50mm Metallic Trunking Knockout serves as a critical component in these systems, providing controlled cable entry points that preserve both the protective properties of metallic trunking and the aesthetic requirements of professional installations.

Technical Specifications and Material Properties

Dimensional Accuracy and Tolerances

The 250mm x 50mm Metallic Trunking Knockout maintains strict dimensional tolerances essential for proper fitting within standard trunking systems. Manufacturing precision ensures consistent gaps and alignment when multiple knockouts are used in the same installation, preventing issues with cable protection and electromagnetic interference shielding.

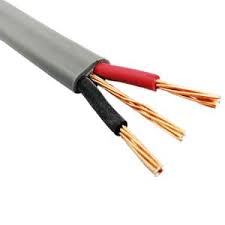

Material Composition and Durability

- Galvanized steel construction: Provides corrosion resistance in diverse environments

- Pre-scored perforation pattern: Enables clean removal without specialized tools

- Smooth edge finishing: Prevents cable jacket damage during installation

- Compatible thickness: Matches standard trunking wall specifications

Electromagnetic Compatibility Features

The knockout design maintains the Faraday cage properties of metallic trunking systems when properly installed. This preservation of electromagnetic shielding proves crucial in environments with sensitive electronic equipment or regulatory EMC requirements.

Installation Methodology and Professional Techniques

Knockout Removal Process

Professional electricians appreciate the 250mm x 50mm Metallic Trunking Knockout for its predictable removal characteristics. The pre-scored pattern allows controlled breakout using standard electrical tools, creating clean openings without metal fragments or sharp edges that could damage cables.

Cable Entry Best Practices

Proper installation involves selecting appropriate cable glands, grommets, or conduit fittings that match the knockout dimensions. The 250mm x 50mm opening accommodates various cable bundle sizes while maintaining ingress protection ratings when sealed correctly.

System Integration Considerations

Each 250mm x 50mm Metallic Trunking Knockout must align with overall cable routing plans to prevent interference with other services, maintain adequate separation distances, and preserve structural integrity of the trunking system.

Applications Across Different Sectors

Commercial Office Buildings

Electrical contractors use these knockouts for routing data cables, power feeds, and HVAC control wiring through metallic trunking systems. The standardized dimensions simplify planning and ensure consistent appearance across multiple floors and zones.

Industrial Manufacturing Facilities

Factory installations benefit from the robust construction of the 250mm x 50mm Metallic Trunking Knockout in environments with vibration, chemical exposure, and mechanical stress. The metallic construction resists degradation from industrial cleaning processes and environmental contaminants.

Healthcare and Laboratory Settings

Medical facilities require reliable cable management that maintains electromagnetic compatibility and allows for frequent reconfiguration. The knockout system facilitates equipment moves and additions without compromising the protective properties of the trunking infrastructure.

Quality Standards and Compliance Requirements

Manufacturing Standards Compliance

The 250mm x 50mm Metallic Trunking Knockout meets relevant international standards for electrical enclosures and cable management systems. Quality control processes ensure consistent performance across production batches and long-term reliability in service.

Installation Code Requirements

Building codes and electrical standards specify requirements for cable protection, fire stopping, and electromagnetic compatibility that influence knockout selection and installation methods. Professional installers understand these requirements and select appropriate components accordingly.

Testing and Certification Protocols

Third-party testing validates the mechanical properties, corrosion resistance, and electromagnetic shielding effectiveness of knockout components. Certification marks provide assurance of compliance with applicable safety and performance standards.

Economic Considerations and Project Planning

Cost-Effectiveness Analysis

The 250mm x 50mm Metallic Trunking Knockout represents a small fraction of total project costs but significantly impacts installation efficiency and long-term system performance. Quality knockouts reduce labor time and prevent costly rework due to dimensional mismatches or premature failure.

Inventory Management Benefits

Standardized knockout dimensions simplify procurement and inventory management for electrical contractors. The 250mm x 50mm size covers a wide range of cable routing requirements, reducing the variety of components needed for typical projects.

Future Modification Flexibility

Pre-installed knockouts facilitate future cable additions and system modifications without requiring major trunking alterations. This flexibility proves valuable in dynamic commercial environments where technology changes drive infrastructure updates.

Installation Challenges and Solutions

Accurate Positioning Requirements

The Metallic Trunking Knockout must be positioned to avoid conflicts with structural elements, other services, and access requirements. Professional installers use detailed drawings and field verification to ensure optimal placement.

Environmental Protection Maintenance

Knockout openings require appropriate sealing to maintain the environmental protection rating of the trunking system. Selection of compatible sealing methods depends on the specific cables, environmental conditions, and regulatory requirements.

Long-term Performance Considerations

Proper installation techniques ensure that knockout modifications do not compromise the structural integrity or protective properties of the trunking system over its expected service life.

Procurement and Supply Chain Management

Specification Requirements

Technical specifications should clearly identify the required knockout dimensions, material properties, and compatibility with the selected trunking system. Metallic Trunking Knockout must match the trunking manufacturer’s specifications for proper fit and performance.

Quality Assurance Practices

Incoming inspection procedures verify dimensional accuracy, material properties, and visual quality of knockout components. These checks prevent installation problems and ensure compliance with project specifications.

No products in the cart.

No products in the cart.